3 Process approach

3.1 Process types

Types, components, elements, management, realization, support

If you cannot describe what you are doing as a process, you do not know what you're doing. Edwards Deming

The word processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) comes from the Latin root procedere = go, development, progress (Pro = forward, cedere = go). Each processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) transforms inputs into outputs, creating added value and potential nuisances.

A processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) has three basic elements: inputs, activities and outputs.

A processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) can be very complex (launch a rocket) or relatively simple (audit a productany outcome of a process or activity (see also ISO 9000, 3.4.2)). A processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) is:

- repeatable

- foreseeable

- measurable

- definable

- dependent on its context

- responsible for its external providers

A processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) is, among other things, determined by its:

- title and its type

- purpose (why?)

- beneficiary (for whom?)

- scope and activities

- initiators

- documents and records

- inputs

- outputs (intentional and unintentional)

- restrains

- people

- material resources

- objectives and indicators

- person in charge (owner) and actors (participants)

- means of inspection (monitoring, measurement)

- mapping

- interaction with other processes

- risks and potential deviations

- opportunities for continual improvement

A processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) review is carried out periodically by the processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) owner (cf. annex 01).

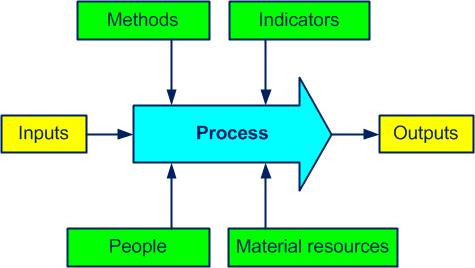

The components of a processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) are shown in figure 3-1:

Figure 3-1. Components of a process

Figure 3-2 shows an example that helps answer the questions:

- which materials, which documents, which tooling? (inputs)

- which title, which activities, requirements, constraints? (process)

- which products, which documents? (outputs)

- how, which inspections? (methods)

- what is the level of performance? (indicators)

- who, with what competence? (staff)

- with what, which machines, which equipment? (material resources)

Figure 3-2. Some elements of a process

Often the output of a processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) is the input of the next processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1).

You can find some examples of process forms in the document pack D 02 and annex 02.

Any organizationa structure that satisfies a need (see also ISO 9000, 3.3.1) (company) can be considered as a macro processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1), with its purpose, its inputs (customeranyone who receives a product (see also ISO 9000, 3.3.5) needs and expectations) and its outputs (products/services to satisfy customeranyone who receives a product (see also ISO 9000, 3.3.5) requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2)).

Our preference is to identify a processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) using a verb (buy, produce, sell) instead of a noun (purchases, production, sales) to differentiate the processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) from the company’s department or procedure to maintain and recall the purpose of the processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1).

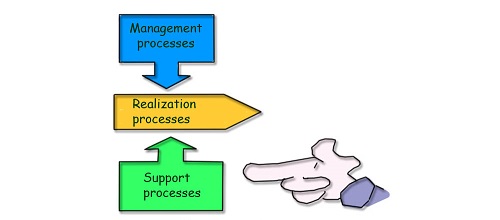

The processes are (as we will see in the following paragraphs) of management, realization and support types. Do not attach too much importance to processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) categorizing (sometimes it is very relative), but ensure that all the company’s activities at least fall into one processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1).

3.1.1 Management processes

Management processes are also known as piloting, decision, key or major processes. They take part in the overall organization and include development of the policy, deployment of the objectives and all needed checks. They are the glue of all realization and support processes.

The following processes can be part of this family:

- develop strategy

- manage risks

- develop policy

- deploy quality objectives

- establish process ownership

- improve

- audit

- communicate

- plan the QMS

- acquire resources

- carry out management review

- measure customer satisfaction

- negotiate contract

- analyze data

3.1.2 Realization processes

The realization (operational) processes are related to the productany outcome of a process or activity (see also ISO 9000, 3.4.2), increase the added value and contribute directly to customer satisfactiontop priority objective of every quality management system (see also ISO 9000, 3.1.4).

They are mainly:

- design and develop new products

- purchase components

- produce products

- sell products

- inspect production

- maintain equipment

- implement traceability (identify and keep history)

- receive, store and deliver

- control nonconformities

- implement preventive and corrective actions

3.1.3 Support processes

The support processes provide the resources necessary for the proper functioning of all other processes. They are not directly related to a contribution of the productany outcome of a process or activity (see also ISO 9000, 3.4.2)'s added value but are still essential.

The support processes are often:

- control documentation

- provide information

- acquire and maintain infrastructure

- provide training

- manage inspection means

- manage staff

- keep accountability

3.2 Mapping

Interactions, process house, core process

Par excellence process “mapping” is a multidisciplinary work with the quality manager as the natural owner. This is not a formal requirement of the ISO 9001 standard but is always welcome.

The three types of processes and some interactions are shown in figure 3-3 and annex 02.

Figure 3-3. Process house

Mapping, among other things, allows you to:

- obtain a global vision of the company

- identify the beneficiaries (customers), flows and interactions

- define (simple) rules for communication between processes

To obtain a clearer picture, you can simplify by using a total of about 15 core processes. A core processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) can contain several sub-processes: for example, the processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) "develop the QMS" can involve:

- develop strategy

- manage risks

- develop policy

- plan the QMS

- deploy objectives

- acquire resources

- establish process ownership

- improve

3.3 Process approach

Benefits, process approach and continual improvement

Simple solutions for now, perfection for later

The fourth principle of quality management is “Process approach” (see § 1.2.1). Some benefits:

- obtain a global vision of the company thanks to the mapping

- identify and manage responsibilities and resources

- achieve effective management of the company based on process indicators

- manage risks that could influence the objectives

Process approach: management by the processes to better satisfy customers, improve the effectiveness of all processes and increase global efficiency

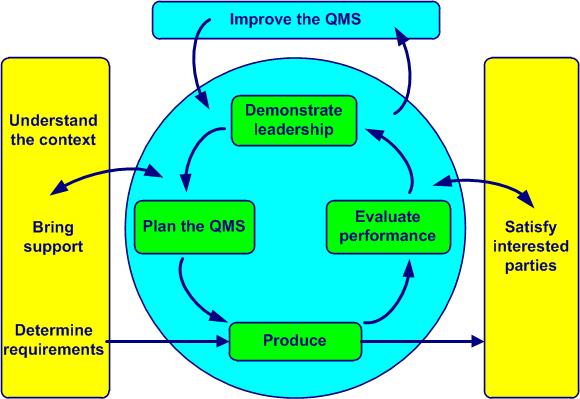

When the process approachmanagement by the processes to better satisfy customers, improve the effectiveness of all processes and increase global efficiency (see also ISO 9004, Annexe B.5) is integrated during the development, implementation and continual improvementpermanent process allowing the improvement of the global performance of the organization (see also ISO 9000, 3.2.13 and ISO 14 001, 3.2) of a quality management systemset of processes allowing the achievement of the quality objectives (see also ISO 9000, 3.2.3), it allows one to achieve objectives that are related to customer satisfactiontop priority objective of every quality management system (see also ISO 9000, 3.1.4), as is shown in figure 3-4 (cf. ISO 9001, 0.2).

Figure 3-4. Model of a QMS based on the process approach and continual improvement

The process approachmanagement by the processes to better satisfy customers, improve the effectiveness of all processes and increase global efficiency (see also ISO 9004, Annexe B.5) (cf. annex 28):

- emphasizes the importance of:

- understanding and complying with customer requirements

- prevention so as to react to unwanted elements such as:

- customer returns

- waste

- measuring process performance, effectiveness and efficiency

- permanently improving objectives based on pertinent measurements

- process added value

- relies on:

- methodical identification

- interactions

- the sequence and

- process management, which consists of:

- determining objectives and their indicators

- piloting related activities

- analyzing obtained results

- permanently undertaking improvements

- allows one to:

- better view inputs and outputs and their relationship

- clarify roles and responsibilities

- judiciously assign necessary resources

- break down barriers between departments

- decrease costs, delays and waste

- and ensures in the long run:

- control

- monitoring and

- continual improvement of processes

For a consulting, support or repair business identifying and defining processes and mapping may not be very useful. More important is to establish and describe for example:

- job descriptions

- staff competence

- the tools to use

- preferred methods for certain recurring cases

- crisis management ("You will not solve the problems by addressing the effects")

- blaming people (“Poor quality is the result of poor management" - Masaaki Imai)

- prioritizing investments (“Use your brain, not your money" - Taiichi Ohno)

.jpg) Minute of relaxation. Cf. game: Process

Minute of relaxation. Cf. game: Process